Drawing

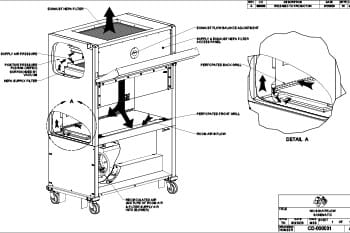

NU-640 Animal Handling Biosafety Cabinet Airflow Schematic

A Class II, Type A2 biosafety cabinet (BSC) designed for small animal handling in a vivarium varies slightly from a BSC designed for Biomedical or Microbiological research. For example, a BSC intended for small animal cage change applications and procedural work will feature a pre-filter to capture animal hair and dander to extend filter life. In the case of model NU-640, the pre-filter is accessible under the work zone.

A motor/blower in the base of the cabinet creates a vacuum, pulling air through the front and back grills and around the edges of the work surface. The motor/blower pulls air through the pre-filter before the air is channeled up the back wall and into the positive pressure plenum surrounded by a vacuum. Air can then take two different paths.

Exhaust Track:

- 30% of air will be exhausted through a HEPA Filter back into the laboratory environment or exhausted through an exhaust flow canopy connected to a dedicated facility exhaust system.

Supply Track:

- 70% of air will be forced through the main supply HEPA filter creating unidirectional downflow air in the work zone. The air will then split on the work surface, pulled by the vacuum created by the motor blower back into the front and back grills.

This airflow pattern helps to protect the laboratory worker and the animal from exposure to potentially hazardous materials and keeps the workspace clean and controlled.