Article

How a Class II, Type B1 Biosafety Cabinet Works

2/22/2021 Seth De Penning

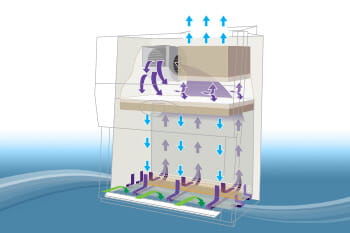

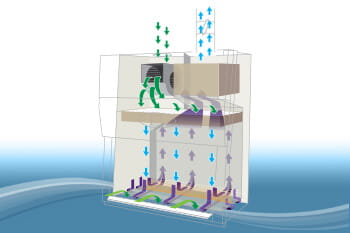

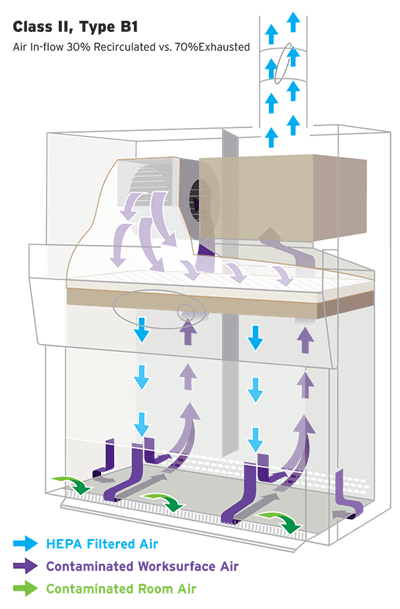

In the Class II Type B1 biosafety cabinet the inflow into the front access opening provides personnel protection, the filtered and laminar downflow in the work zone provides product protection, and the filtered exhaust provides environmental protection just like they do in any Class II biosafety cabinet. However, the functioning of the cabinet is a cross between a Type A2 and Type B2. Like on the Type A2, the inflow and the front part of the downflow are pulled into the front airflow grill that leads them to a space under the work surface through which they can flow backwards towards the rear of the cabinet. From there, the air travels up a vertical channel to a place at the top of the cabinet known as a plenum. This plenum is connected to the supply HEPA filter below it and routes the air through that HEPA filter towards the work zone as downflow. The Type B1 cabinet’s internal blower-motor powers this circuit of air that comprises about 30% of the air flowing through the cabinet. However, the Type B1 cabinet must be connected to an external exhaust blower that will power another circuit of air that occurs in tandem. This external blower pulls the back part of the cabinet downflow into another airflow grill, at the back of the work zone, and subsequently through its own vertical channel up to a second plenum at the top. This plenum, however, is instead connected to the exhaust HEPA filter through which that external exhaust blower now extracts this air before continuing to pull it towards itself through the ductwork. This flow of air comprises the other 70% of the air flowing through the cabinet. As was the case for the Type B2 cabinet, if the external exhaust blower ever stops working and no longer creates enough “pull” to keep half the work zone air flowing towards the back airflow grill, it is critical that the internal blower no longer force air down to that work zone where it might flow out and carry particulate towards the user.

REFERENCES

- NSF International. NSF/ANSI 49-2019. Biosafety Cabinetry: Design, Construction, Performance, and Field Certification. 2020.

- Centers for Disease Control and Prevention. Biosafety in Microbiological and Biomedical Laboratories (BMBL) 5th edition. Appendix A. Atlanta, GA: CDC, 2009.

- Controlled Environment Testing Association. CETA Application Guide for the Exhaust System Requirements of Class II, Type B Biosafety Cabinets. CAG-007-2010. March 24, 2010.

- Controlled Environment Testing Association. CETA Application Guide CAG-007: Exhaust System Requirements of Class II Biosafety Cabinets. CAG-007. Revised September 2020.