Article

Selecting an Ultralow Freezer Back-up System

5/21/2021Ultra-low temperature (ULT) freezers are widely used for high-capacity storage of samples such as genomic material, cell lysates, tissue homogenates, or vaccines which they maintain at or below -80°C. Provided they are well cared for and undergo regular preventative maintenance. They can preserve sample integrity for months or even years, making them a precious asset to any lab working with large quantities of irreplaceable material. To ensure samples in ULT storage remain protected in the event of an unexpected power outage, most end users choose to integrate a ULT backup system. Here, we explain some features and benefits of the available options to help you decide which ULT backup system is right for you.

A power outage can be catastrophic

When a power outage occurs in the lab, it is usually pretty apparent – the lights go out, the air conditioning shuts down, and various alarms begin to sound. Although researchers can usually take immediate action to secure their working environment and resolve the issue, for example, by closing down biological safety cabinets (BSC) and contacting the appropriate individual such as your facilities management team or EHS department to alert them of the problem, the impact of a power outage can be catastrophic when no one is around, particularly where large quantities of temperature-sensitive material are stored in a ULT freezer.

Although many modern ULT freezers incorporate specialized refrigerants and combine foam with vacuum insulation panels to enable them to maintain a low temperature for several hours without power (provided the door remains closed), these measures can only go so far. Older models can rapidly defrost thoroughly, leading to any sample material becoming unusable. Irrespective of the make and model of your ULT freezer, connecting it to a ULT backup system will not only prevent precious samples from being compromised by a power outage but will also avoid the inconvenience of being called into the lab in the middle of the night to transfer sample material to alternative storage.

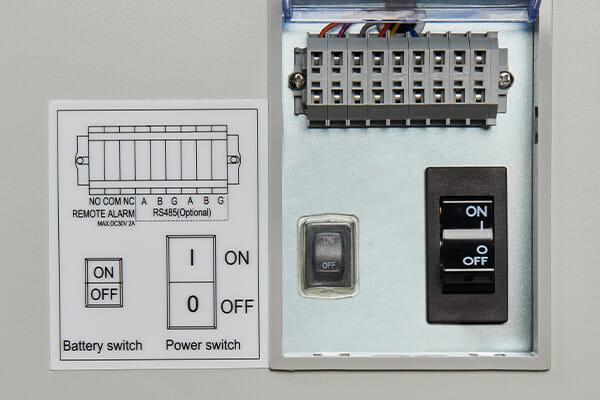

Battery backup systems DO NOT OPERATE COOLING FUNCTIONS but provide a temporary solution to power system electronics.

Modern Ultralow Freezers feature a battery backup system. The battery backup system provides researchers a temporary solution to power the freezer's electronics in a power outage. The backup system does not provide power to the freezer's compressors to maintain temperature. Under normal operating conditions, this remains in standby mode and is continually charged by the main supply. However, when a power outage occurs, the battery backup system is automatically activated to begin powering the ULT electronics. The purpose of the battery backup is to maintain the alarm system to notify a user within a range that there has been a power failure. Once the chamber starts warming, and a set point is reached, the high-temperature alarm will sound. Once the power is restored, standby mode is reinitiated so that the battery backup system can recharge in preparation for subsequent use. Although the amount of runtime provided by a battery backup system varies, many modern ULT freezers are fitted with systems that provide up to 72 hours of power to electronics and alarms.

The battery backup system should also provide surge suppression. This is a safeguard against sudden power spikes that could damage the freezer's compressor and can mainly be of value to labs located in regions where the power supply is known to fluctuate, such as areas prone to hurricanes. Surge suppression also protects the ULT freezer when standby generators undergo scheduled testing and from the abrupt drop in power that can occur when the outage is over. Multiple instruments simultaneously power up, making it an effective means of preserving samples and prolonging the ULT freezer's useful life.

CO2 or LN2 backup systems use liquid gases to maintain temperature

Another approach to maintain a ULT freezer at -80°C during a power outage is to use a liquid carbon dioxide (CO2) or liquid nitrogen (LN2) system. CO2 and LN2 backup systems are backup kits that provide a pathway into the freezer. As the name suggests, these rely on liquid gases to keep samples at low temperatures. A backup module controls the addition of coolant to the freezer chamber when the temperature rises above a set threshold. The main differences between the two systems are the lowest temperature that they can achieve and the length of time the liquid gas remains stable in the tank. While liquid CO2 can maintain temperatures in the region of -55°C to -70°C and lasts for months, liquid nitrogen is capable of temperatures down to -85 oC but depletes faster over time and therefore requires monitoring.

Choosing between CO2 and LN2 depends on the desired temperature needed for the research samples and the expected duration of the outage. As a lab manager or facilities professional, work with the Principal Investigator to develop a backup in the event of a catastrophic failure. Identify the proper temperature needed for samples to survive. Is minus 80°C needed, or can the samples be allowed to warm? Also, plan for the duration. Is 24 hours needed, 72 hours to cover the weekend, or additional buffer time to accommodate the unit not operating at setpoint during the power outage. Finally cost. What type of investment is needed to install and maintain a backup system and the risk if one is not put in place.

A key consideration for both surrounding health and safety is that end-users require training to handle liquid gases correctly. It is also critical that there be adequate space in the lab for the gas storage tanks and that the entire system, including the injector, be checked regularly for assurance it will perform when needed. For additional peace of mind, battery backup systems and CO2 or LN2 backup systems are often used in combination.

Remote monitoring offers tighter control

By tracking cold storage conditions over time, remote monitoring systems can provide an extra level of protection for samples held in ULT freezers. For example, by alerting end-users to the battery backup system having been deployed while no one was in the lab, checks can rapidly be performed to determine how long a power outage lasted and confirm that the freezer chamber's temperature remained stable during that time. Remote monitoring can also track ambient conditions, allowing these to be kept constant so that the ULT freezer is not required to work too hard. This helps to ensure many years of reliable service and save on the expense of having to replace a ULT freezer earlier than anticipated.